Get in contact with us

Telephone

Austria

Possible applications through maximum design freedom

The unique construction and flexible design of the bigHead® enable a secure connection in workpieces made of plastic or composite materials without pre-drilling or punching. The bigHead® fasteners can be embedded directly during the production process or subsequently integrated or glued onto the workpiece.

The challenge of finding the right connection solution for composite materials

With the increasing use of composite materials as a result of expanding areas of application, the challenge of finding the right connection solution for every application increases.

Our white paper examines some proven interconnect solutions within an ever-growing market.

We wish you exciting insights and enjoy reading.

> Request the white paper now

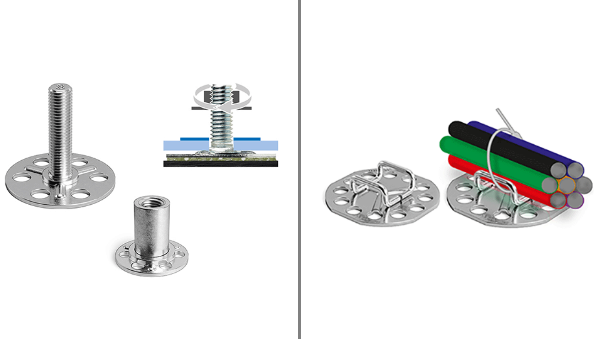

bigHead® possible applications

bigHeads® are the ideal products for creating secure connections on and in a wide variety of components. The fastening elements enable the efficient assembly of an assembly as well as a combination with a second connection element, such as:

- Threaded connections for assembling an assembly (left picture)

- Cable holder for fixing cable ties (right picture)

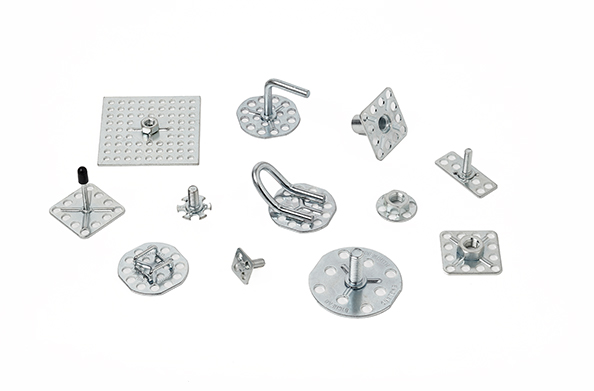

bigHead® range

Core range

A pre-defined range of 156 products, supported by usage guidelines and technical data. Core range products can be used in both post-process and co-process applications.

Features

Extended range

Selected product ranges, in a wider variety of fixing type and size combinations.

Features

- Non circular heads, including square and rectangle

- Further circular head diameters

- Additional fixings: nuts, nails, loops, pins, etc.

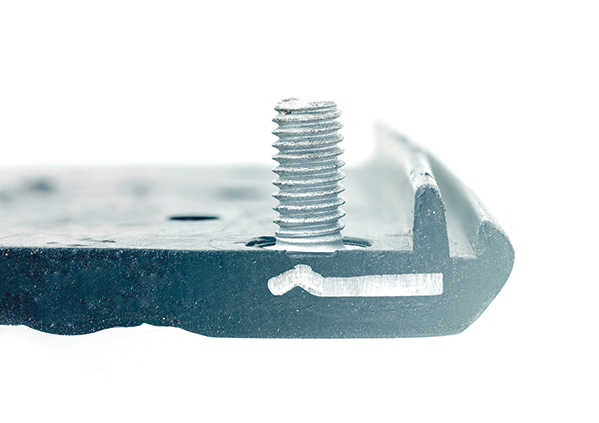

Post-process bonding

Adhesive bonding is the most common post-process installation technique for bigHead® products, although some solutions utilise mechanical fixation. Adhesive bonding is suitable for both metallic and non-metallic materials, including sandwich materials.

Features

Co-process embedding

Embedding or co-processing a bigHead® includes the fastener in the parent component’s manufacturing process, such as moulding.

Features

Your design partner

Working in partnership from early on in the design phase, bigHead® can help you avoid design, fastening or assembly compromises.

bigHead® has the knowledge and expertise to support your design and engineering activities across multiple stakeholders.

Features

- Technical information and guidelines

- Design and assembly review

- Materials and manufacturing process integration

- Applications engineering support

- Testing and validation

- Prototyping and samples

Special solutions

If the pre-defined core and extended ranges don’t meet your exact requirements, bigHead® can offer a multitude of ways for you to optimise your product solution.

Features

- Different sizes and configurations for maximising fastening possibilities

- Coatings options to suit wide-ranging requirements

- Features for optimising manufacturing process integration, assembly operations

- Products that fulfil specific application or performance requirements

- Design and development from prototype to full-scale production

- Testing and validation and applications engineering support