Get in contact with us

Telephone

Austria

Accuride is a global designer and manufacturer of movement solutions. For over 50 years, we’ve engineered movement systems into cabinetry, machinery, and other applications around the world. Learn more about our journey below.

Slide system overview

Light duty - 50kg and less

- DZ2421- Light duty telescopic slide with low profile

- DZ2002 - Two-way travel drawer slide double extension mounting tabs

- DZ0201 - Part extension industrial slide

- DZ2807- Electronic enclosure slide for 19 inch racks

Medium duty - 51kgs to 99kgs

- DZ3507 - Medium duty slide with lock-out and disconnect

- DS5334 - Medium duty stainless steel telescopic slide

- DZ3932 - Medium duty full extension cabinet drawer slide

- DZ3306-DO-2 - Medium duty slide with lock-in and detent-out

Heavy duty - 100kgs and more

- DA4120 - Aluminium part extension slide

- DZ5321- Heavy duty over travel slide

- DZ6026 - Heavy duty two-way travel slide

- DZ7957-2 - Heavy duty slide front disconnect

How to select a slide

Load rating

- Load ratings quoted are the maximum for a pair of side mounted slides installed 450mm apart, unless otherwise stated

- Load ratings will change according to the length of the slide. See individual datasheets for details

- In general, wider drawers require a slide with a higher load rating and a cross section designed to withstand lateral stress. Our technical department will be pleased to advise you

- See individual datasheets for details of cycle rates used for testing

- The measurements are taken between and at the midpoint of the drawer member and are given in kg

- Load ratings quoted are dynamic. Accuride® slides have a 100% static safety factor in the extended position

- Horizontally (flat) mounting the slides reduces the load capacity to at least 25% of the vertical (side) mount capacity. Not all slide models can be used in flat mount applications

- Deflection of flat mounted slides will vary depending upon the application. We recommend prototyping to determine that the deflection is within an acceptable range

- We advise clients to test slides in the intended application

- All fixing positions should be used to achieve maximum load rating

- Appropriate fixing materials must be used

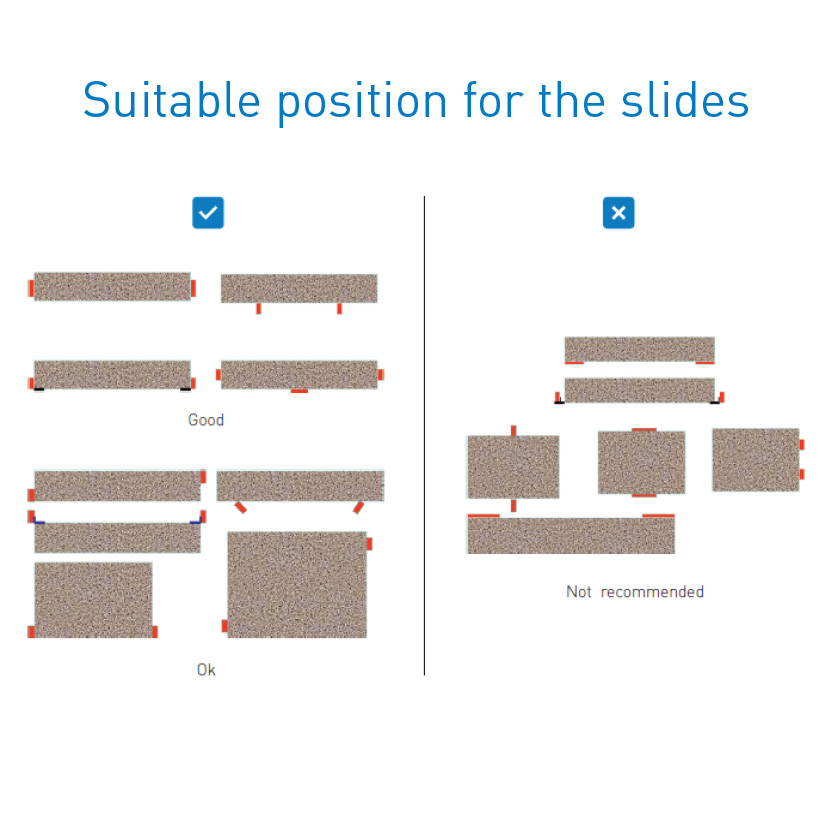

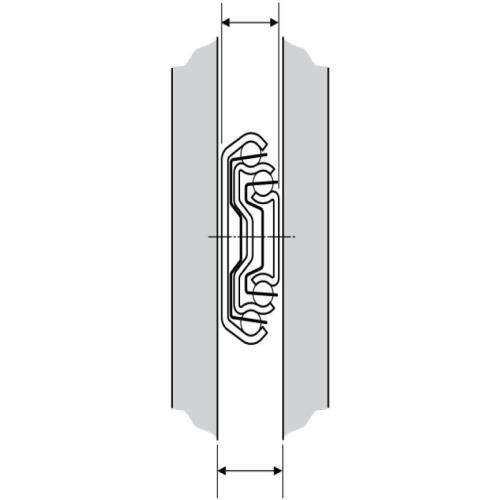

- Mounting slides in different configurations will affect performance and load rating. See the illustrations on the left

- Recommended drawer slide position for maximum stability

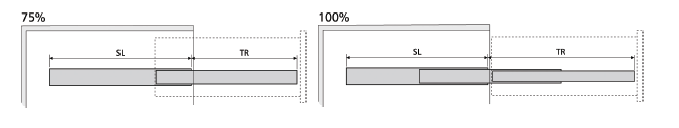

Extension or travel

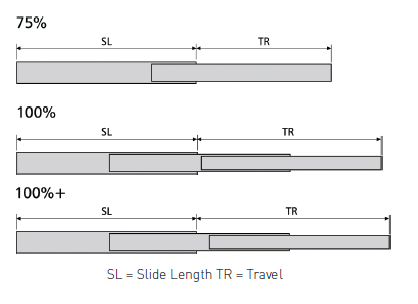

- 75% extension – drawer opens approximately

- 75% of the total length of the slide

- 100% extension – drawer opens the same amount as the slide length

- 100%+ extension – over-travel is achieved. The drawer opens in excess of the slide length

- Most full (100%) extension slides have nominal overtravel

Slide length

- Slide length is measured as the longest dimension of a fully closed slide. As a rule, always use the

maximum length allowable in the application

Side space

- The amount of space necessary to accommodate the thickness of the slide assembly

- For optimum performance allow between +0.2mm and +0.5mm over the nominal slide thickness, e.g. for a 12.7mm slide, the side space allowance should be between 12.9mm and 13.2mm

- Precision slides cannot absorb large gap deviations between the cabinet and the drawer. The cabinet and drawer must be square and parallel to each other for optimal working of the pair of slides

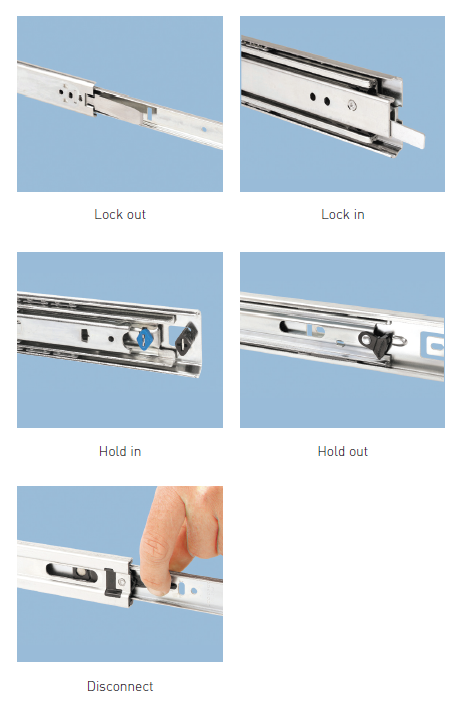

Determine any special features required

- Disconnect allows simple connect/disconnect from the slide assembly

- Lever – disconnect is achieved by releasing an internal lever and by pulling the drawer firmly through the resistance of the ball retainer

- Push latch – a latch is pressed to release the drawer and disconnect is achieved by pulling the drawer firmly through the resistance of the ball retainer

- Locks hold the slide either closed or open and a lever must be actuated to move the slide

- Hold-in and hold-out (DO) keeps the slide open or closed until extra force is applied

- Self close (SC) slides include a spring attachment designed to close the slide and prevent bounce back

- Dampened soft-close (EC) slows the closing action for a controlled and smooth operation

- Touch release (TR) slides open with pressure to the front of the slide.

- Mounting options, for example, bayonets and brackets

- Cam drawer adjust allows minute adjustment to the drawer front for easy alignment. Standard feature on 2132 and 3832 series slides

- Shock blocks are hardened steel pins that provide an interference fit between the slide members to minimize the amplification of vibration and reduce the damaging effects of shock in the closed position. Available on slide 0522 as standard

- Standard features suffixes: see the image on the left