Get in contact with us

Telephone

Austria

Reliable fastening of different materials using an ultrasonic process

Above all in lightweight structural engineering, innovative fastening solutions which offer the highest degree of reliability and efficiency are in great demand. Through the introduction of ultrasonic energy to fixing and fastening solutions, joining of element is accomplished safely and in many cases without much preparation. Ideally, the connecting element should become part of the carrier material.

The MM-W™ technology originated from the WoodWelding® technology, which has been in use for years not only in woodworking but also in surgery.

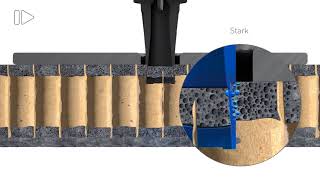

Now is the time to use the digitalization boost and optimize processes

MultiMaterial-Welding is revolutionizing joining technology with its technology platform to give you exactly the digital advantage. In our video, we would like to demonstrate how the complete automation of plant engineering is simplified and how the entire production chain can be digitized for faster and more economical production processes.

Advantages

- Significantly stronger connections than with many other fastening methods

- Can be used without pre-setting to take up tolerance

- Clean processing, as no additional materials or or pre-treatment of surfaces is required and no waste is produced

- Statistical check on the process, which guarantees the quality of the individual fastenings

- The technology is used in a wide range of industrial processes and in other industries, such as medicine and the furniture industry

Get your free white paper now

How can machine learning be optimally used in lightweight construction?

With its SmartSolutions software, Multimatierial-Welding offers an initial approach to digitization and quality control of fastening processes.

Our free white paper gives you comprehensive insights into the fastening technology platform.

- Effects of change and the future of the transportation industry

- What influence does digitization have on fastening processes?

- Machine learning - meaning and benefits

- SmartSolution technology - advantages for your company

- Efficient fastening of different materials

- Cost reductions through automation of fastening processes

Simply request the white paper at the following link and benefit from our expert knowledge.

> Request the free white paperJohann Borgers GmbH uses the technology platform MultiMaterial-Welding

Johann Borgers GmbH develops custom damping, insulation and equipment solutions for a number of different passenger car and truck models. Different joining techniques are used depending on the installation location on the outer body as well as in the engine, passenger and trunk compartments. With the new MultiMaterial -Welding (MM-W) technology from KVT-Fastening, Borgers was able to implement a fastening variant for a trunk floor with a paper honeycomb core for a luxury SUV, which could not be realized from a technical point of view using conventional methods. > read moreMM-Welding® - Fastening Technology that pays off

Manufacturing companies do not only expect proven technologies, but also efficiency and low cost when selecting fastening solutions. But how do you find the optimal process among so many available options? Florian Beer, Managing Director of KVT-Fastening GmbH gives interesting insights into the topic of MM-Welding® in an interview.

> Interview

Webinar

Benefit from our expert knowledge, gain interesting insights into MM-Welding®. The webinar was already held but you can download the webinar for free.

Topic: Connecting Modern with MM-Welding®

- Speaker: Lasse Behrmann, MSc Project Manager Lightweight Technologies, KVT-Fastening

- Language: The webinar was held in English - but we are also happy to answer your questions in German

Get in contact with us

Get in contact with us

We are happy to answer your questions.

MM-Welding® technology portfolio

LiteWWeight® Pin

This is a family of fasteners with easy one-sided access assembly process designed to realize fast and strong fixation on sandwich structures with internal honeycomb or similar patterns.

Application

- Fastening on foamed honeycomb structures and/or porous building components

- Typical application: Load floor, parcel shelf, roof panel

Features

- Full integration in substrate possible

- High strength: Pull-out forces of higher than 1000N can be achieved through deep integration into HCB material

- Very fast processing time of ~1 second

- No pre-drilling necessary in most cases

- Possible to pierce through thick decor materials

- Placement directly at the edge of the material possible

- The different fastener geometries enable different types of applications

> Download product information

> Video

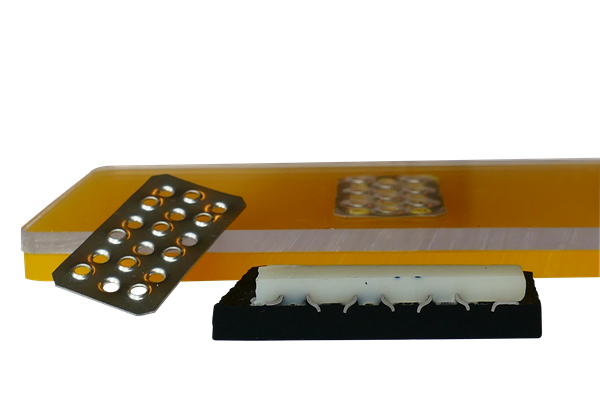

LiteWWeight® Double Pin

This fastener is designed to realize fast and strong fixation that can be designed for plastic direct screws, with a metric internal thread or even with a through-hole. The fastener consists of a sleeve, as slide and optionally a metallic insert, which can be selected according to the application.

Application

- For connection into lightweight sandwich panels made of aramid, polypropylene, and more

- Nomex honeycomb panels for aerospace applications: In aerospace industry, certification is crucial for the acceptance of each part. The LiteWWeight® Double Pin includes standard materials for aerospace, and is an ideal replacement for gluing where material content complicates the certification process.

- Polypropylen honeycomb panels: Internal cavities of polypropylen honeycomb panels make it difficult to install standard connectors such as screws as they don’t have a structure to hold on to.

- The LiteWWeight Double Pin® is designed to attach strongly to this type of material, and if necessary allows the inclusion of a metallic thread.

Features

- High versatility: can contain a clearance hole, a threaded hole or a metallic insert (M3 to M8)

- Quick installation process time of < 0.7 seconds

- High strength due to creating form lock to top-layer and conventional weld-connection to bottom-layer

- Full integration in substrate possible

- Pull-out forces of higher around ~ 2000 N can be achieved through deep integration into HCB material

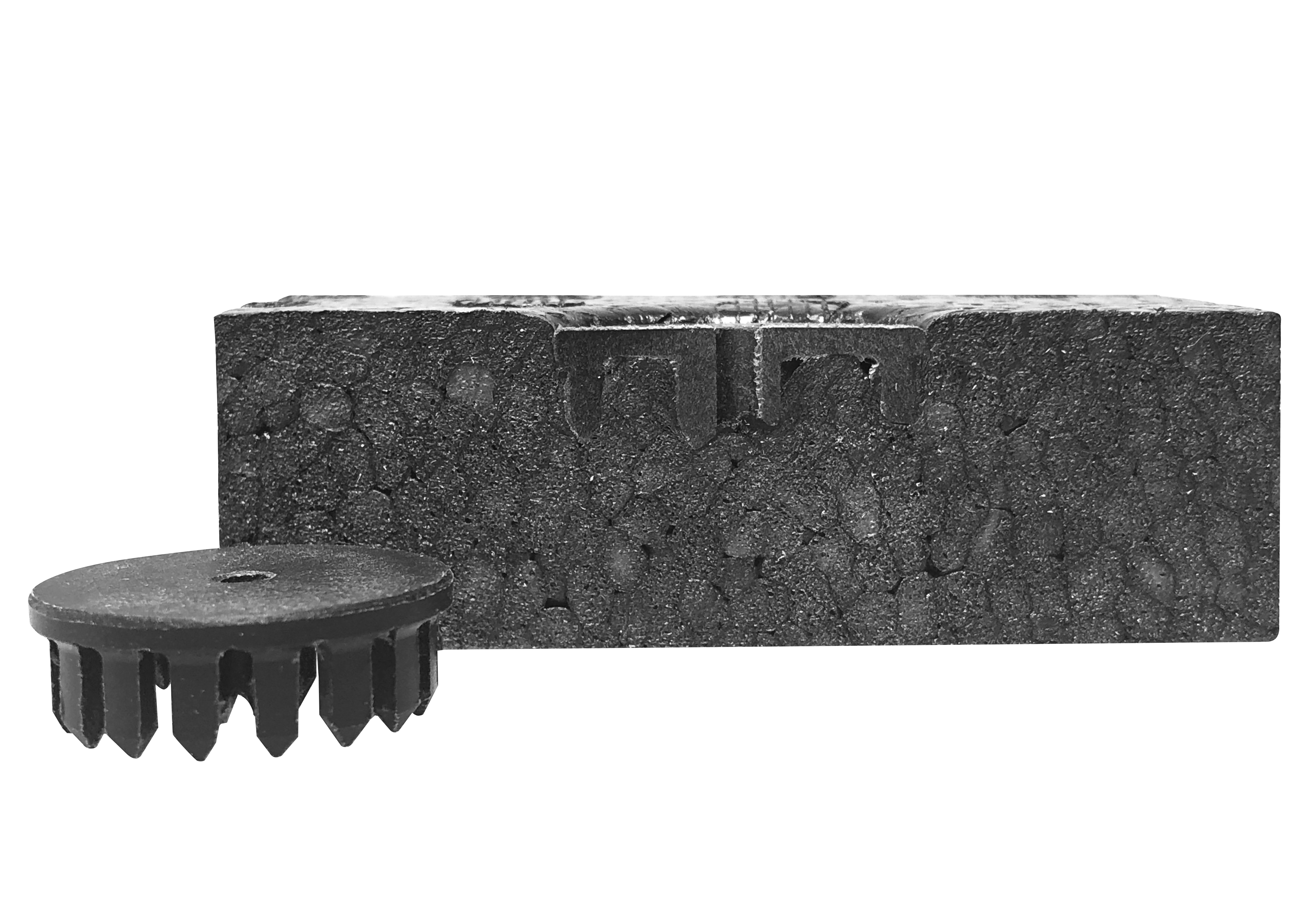

LiteWWeight® zEPP

LiteWWeight® zEPP is a fast and efficient fastening technology for all expaned polyproylene (EPP) materials based on the innovative MM-Welding® process.

Application

- Solution for fixation into expanded polypropylene (EPP) foam

- Dowel solution to create a durable threaded fixation point with or without metal insert

Features

- Very fast cycle times (~1 second)

- High pull-out force due to optimal anchoring with the EPP material

- Very high torque transmission possible due to MM-Welding® specific "Anti-Turning" geometry

- Full integration into the substrate

- Placement directly at the edge of the material possible

- Low overall height of the fastener increases design freedom

- Applicable for all density ranges

- No pre-drilling necessary

.jpg?h=533&w=800&la=en&hash=3B9A8CB5918C18D6370F541EFEAAD97AA8EAE5D1)

InWWerse® Fastener

Based on the innovative MM-Welding® process, the InWWerse® Fastener Technology takes the industry proven advantages and features to another exciting field of applications. The MM-Welding® engineers have developed a novel fastening system which allows to precisely establish an immediately loadable connection point onto thermoplastic substrates.

Application

- For creating connection points on thin polymer parts

- Ideal for thermoplastic polymers with or without reinforcement

- Discrete connections possible. Neither marks nor fastener appearance on distal side visible

- Suitable for decorative and structural parts within automotive, aviation or rail industry

Features

- Very fast processing time of only 1 second

- Suitable also for low wall-thicknesses

- No pre-hole or through-hole required

- Strong form locking due to innovative crater shaped design

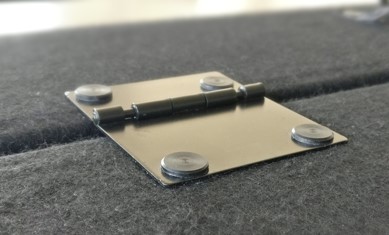

InWWerse® Disc

Fastening solution for joining dissimilar thermoplastic as well as very thin materials (< 2.5 mm) without creating marks.

By using the unique MultiMaterial-Welding® ultrasonic technology it provides a very quick and reliable processing, superior to adhesive bonding in many applications.

Application

- Bonding thin-walled polymer components

- Ideal for thermoplastic polymers with or without reinforcement

- Discrete connections possible. Neither marks nor fastener appearance on distal side visible

- Suitable for decorative and structural parts within automotive, aviation or rail industry

Features

- Use for conventional, non-weldable polymer combinations

- Thin-walled polymer parts without affecting the opposite surface

- Very short cycle times

LiteWWeight® Lotus

LiteWWeight® Lotus is a fast and reliable connection concept for fibrous components and textile structures.

Application

- Fastening in woven and non-woven structures

- Typical applications: Passenger car floor trim, heat shields, wheel arch liners, headliners, NVH

Features

- Very fast cycle times

- High strength due to intensive integration in the fibre matrix

- Simple and more complex 3-D geometries (due to direction of motion of the fastening element only being in the z-direction)

- Ideal integration into textile structures possible

Reliable fastening of different materials using an ultrasonic process

Above all in lightweight structural engineering, innovative fastening solutions which offer the highest degree of reliability and efficiency are in great demand. Through the introduction of ultrasonic energy to fixing and fastening solutions, joining of element is accomplished safely and in many cases without much preparation. Ideally, the connecting element should become part of the carrier material.

The MM-Welding® technology originated from the WoodWelding® technology, which has been in use for years not only in woodworking but also in surgery.

License reference

MM-Welding® technology is based on the patented WoodWelding® technology of WoodWelding SA and is licensed by MultiMaterial-Welding AG, Switzerland.

MM-Welding® technology is a proprietary technology of MultiMaterial-Welding AG, Switzerland, and is licensed by Bossard AG.