Applications:

- Wearables (smart watches, cameras, fitness bands, headphones, etc.)

- Computers and Laptops

- Tablets/Readers

- Cell/Smart Phones

- Gaming/Hand Held Devices

- Infotainment/Automotive Electronics

We are happy to help

Thanks to the wide and comprehensive range, there are many ways to use them for a wide variety of applications.

We are happy to support you in the search and selection of the best product to solve your challenges.

Take advantage of our many years of experience and find out how our self-clinching solutions can create real added value for your company. We offer:

- C-parts optimization - reduction of the variety of parts

- Development partnership

- Automation and process monitoring

- Complete systems - everything from a single source

We advise you quickly, free of charge and competently.

> Contact us now

Types of fasteners

Types TA™/T4™ microPEM® TackPin® fasteners

Enable sheet-to-sheet attachment, replacing costly screw installation in applications where disassembly is not required.

Features:

- Simple, press-in installation for secure attachment

- Proven self-clinching technology resists vibrational loosening

- Replaces micro screws, eliminating installation issues including:

- Cost of locking patch

- Cost of threaded insert or tapped hole

- Cost of driver bits

- Cost of rework due to cross-threading and driver bit cam-out

- Top sheet can be any material

- Can be installed automatically

- Twists out (unscrew) if removal is necessary. Can be reinstalled one time using a thread locking adhesive.

Type MPP™ microPEM® pins

PEM® Type MPP, self-clinching microPEM® pins are ideal for today’s compact electronic assemblies. Simply pressed into a properly sized mounting hole, these micro pins clinch permanently into place. They can be installed into a variety of sheet materials up to HRB 92 / HB 195 in hardness and they offer excellent corrosion resistance.

Features:

- Satisfy demanding micro positioning and alignment applications

- Head mounts flush into panels as thin as 0,5mm / .02

- Chamfered end makes mating hole alignment easy

- Can be installed into stainless steel sheets

- Can be installed automatically

- Excellent corrosion resistance

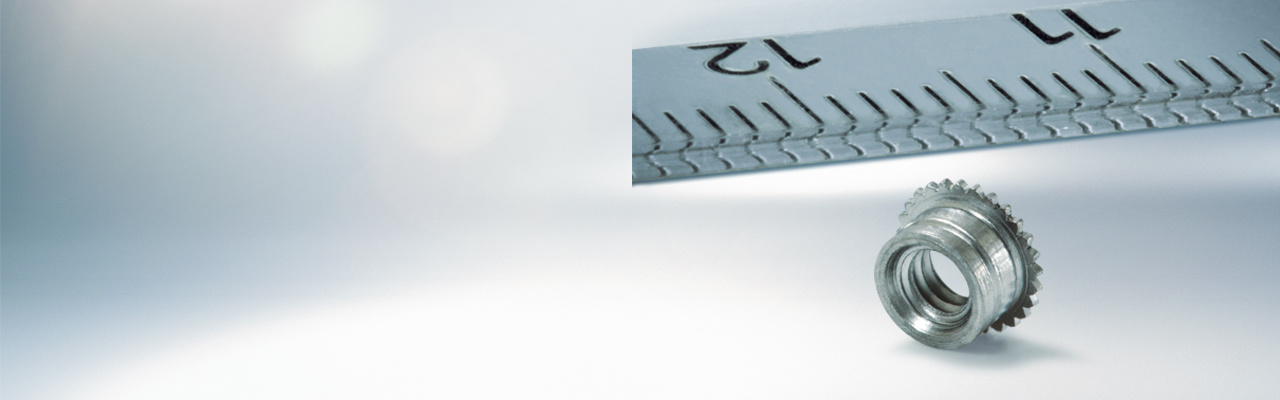

Type MSO4™ microPEM® self-clinching standoffs

Designed for mounting and/or spacing in extremely limited space applications.

Features:

- Designed for mounting and/or spacing in extremely limited space applications

- Can be installed into stainless steel sheets

- Have stronger threads than weld standoffs because they are made from heat-treated 400 Series Stainless Steel

- Can be installed automatically

Types TKA™/TK4™ microPEM® TackSert® pins

Designed with diagonal knurl to hold a top panel to a bottom panel or chassis by broaching into the bottom panel/chassis. Type TKA pins are suitable for broaching into plastic applications, and Type TK4 pins are suitable for broaching into castings and brittle materials.

Features:

- Secure panels to common cast materials such as magnesium and aluminum. Also appropriate for attaching panels to plastics such as ABS and to P.C. Boards.

- Simple, press-in installation. Does not require heat or ultrasonics.

- Alternative to micro screws, eliminating the need to tap or use threaded inserts

- Top sheet can be any material

- Low-profile head

- Eliminates the following:

- Cost of screw

- Cost of patch to prevent loosening

- Cost of threaded insert or tapped hole

- Cost of driver bits

- Cost of rework due to cross-threading and driver bit cam-out

- Can be installed automatically

Type SMTSO™ microPEM® surface mount fasteners

These fasteners for compact electronic assemblies attach to P.C. Boards for nut/standoff applications. These fasteners mount on P.C. Boards in the same manner and at the same time as other surface mount components prior to the automated reflow solder process.

Features:

- Hex shaped barrel provides optimal size/performance

- Provided on tape and reel

- Reduces board handling

- Can be installed automatically

Type TS4™ microPEM® TackScrew™ fasteners

Enable cost effective sheet-to-sheet attachment by simply pressing into place. Can be removed by simply unscrewing, similar to other threaded fasteners.

Features:

- Simple, press-in installation for secure attachment

- Proven self-clinching technology resists vibrational loosening

- Replaces micro screws, eliminating installation issues including:

- Cost of locking patch

- Cost of threaded insert or tapped hole

- Cost of driver bits

- Cost of rework due to cross-threading and driver bit “cam-out”

- Top sheet can be any material

- Can be installed automatically

- Twists out (unscrew) if removal is necessary. Can be reinstalled one time using a thread locking adhesive.